11mm aluminum crimp top seals have a larger opening to ensure proper needle penetration 2ml, 12X32mm vials are manufactured of Clear, Type 1

Class A or Amber, Type 1 Class B borosilicate glass and include a write-in patch for sample identification

Caps are made of high quality laquered aluminum, 0.010" thick Available cap colors include silver, red, and green

Our septa use only the highest quality materials to ensure proper function and can be pre-slit to ease needle penetration

0.030" White Silicone sandwiched between two layers of 0.005" Red PTFE

Designed for the most demanding GC procedures such as trace analysis, or longer cycle times between injections

High quality silicone compounds are used to ensure proper re-sealing and reduced chances of coring

Works well with blunt tip needles

Products Features+

|

|

|

|

|

| Part No. | V1117(Economy) V1113(Expansion 33) |

V1127(Economy) V1123(Expansion 33) |

V1137(Economy) V1135(Expansion 51) |

V1147(Economy) V1145(Expansion 51) |

| Description | 1.5ml wide opening crimp-top vial, clear 11.6*32mm USP 1 | 1.5ml wide opening crimp-top vial with write-on spot , clear 11.6*32mm USP 1 | 1.5ml wide opening crimp-top vial, amber 11.6*32mm USP 1 | 1.5ml wide opening crimp-top vial with write-on spot, amber 11.6*32mm USP 1 |

|

|

|

|

| Part.No. | SC111111 | SC112111 | SC113111 |

| Description | White PTFE/red Silicone septa, 11mm crimp-top aluminum cap, 5.5mm centre hole | Red PTFE/white Silicone septa, 11mm crimp-top aluminum cap, 5.5mm centre hole | Red PTFE/white Silicone/red PTFE septa, 11mm crimp-top aluminum cap, 5.5mm centre hole |

.jpg)

.jpg)

|

Crimp-top Vials,Aluminum Caps and septa, Wide opening ND11 100pcs/pack |

|

|

S111 |

white PTFE/red Silicone septa Φ11*1mm temperature resistant -60℃-200℃ |

|

S112 |

red PTFE/white Silicone septa Φ11*1mm temperature resistant -60℃-200℃ |

|

S1111 |

pre-slit white PTFE/red Silicone septa Φ11*1mm temperature resistant -60℃-200℃ |

|

S1122 |

pre-slit red PTFE/white Silicone septa Φ11*1mm temperature resistant -60℃-200℃ |

|

SC111111 |

white PTFE/red Silicone septa, 11mm crimp-top aluminum cap, 5.5mm centre hole |

|

SC112111 |

red PTFE/white Silicone septa, 11mm crimp-top aluminum cap, 5.5mm centre hole |

|

SC1111111 |

pre-slit white PTFE/red Silicone septa, 11mm crimp-top aluminum cap, 5.5mm centre hole |

|

SC1122111 |

pre-slit red PTFE/white Silicone septa, 11mm crimp-top aluminum cap, 5.5mm centre hole |

|

V1117 |

1.5ml wide opening crimp-top vial, clear 11.6*32mm |

|

V1127 |

1.5ml wide opening crimp-top vial with write-on spot , clear 11.6*32mm |

|

V1113 |

1.5ml wide opening crimp-top vial, clear 11.6*32mm |

|

V1123 |

1.5ml wide opening crimp-top vial with write-on spot, clear 11.6*32mm |

|

V1135 |

1.5ml wide opening crimp-top vial, amber 11.6*32mm |

|

V1145 |

1.5ml wide opening crimp-top vial with write-on spot, amber 11.6*32mm |

Technical Information+

Vial Finish Specifications

Test Report

.jpg)

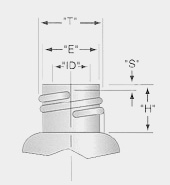

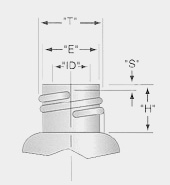

Screw Thread Finishes

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

Typical GPI finishes found in the chromatography field are as follows:

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

Glass Technical Information

Borosilicate - A glass that is high in silicate and having at least 5% boron oxide.

Linear Coefficient of Expansion - Fractional change in length of glass per degree change in temperature.

Strain Point - Maximum temperature to which glass should be heated during use"

Types of Glass:

USP Type - Pharmaceutical glass containers can be classified as USP Type I, II, III or NP.

Type I - Borosilicate glass represents the least reactive glass.

Type I glass has the least pH shift. (Lowest leaching characteristics) Coefficient of Expansion = 33 or 51 for Clear and 51 for Amber

Type II - is de-alkalized soda lime glass with higher levels of sodium hydroxide and calcium oxide.

Type III - soda lime glass - cannot be autoclaved.

Type NP - general purpose soda-lime glass used where chemical durability and heat shock are not factors.

Coefficient of Expansion = 92.

GLASS PROPERTIES

| Color |

Clear |

Amber |

|---|---|---|

|

Linear Coefficient of Expansion |

33 |

51 |

|

Strain Point (Degrees Celsius) |

515 |

535 |

|

USP Class Type |

Type 1 |

Type 1 |

|

Light Protection |

No |

Yes |

Plastic Properties

| Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic |

|---|---|---|---|---|---|

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

Process Flow Diagram+

The workers clean the tubing with cloth

The workers plug the tubing into machine for making vials

The vials are transferred to QC for Physical Test

The workers put the tested vials into one big package (500-800pcs/pack)

The workers get the vials from big package and put the vials into one special tray.

Put the tray with vials into the Water injection machine

The vials in tray will be transferred to next step for Ultrasonic oscillations.

The vials in tray will be transferred to Jilt water machine.

The vials in tray will be transferred to Infrared drying case.

The workers will collect the vials after vials are dry.

The vials in tray will be transferred to next step for Ultrasonic oscillations.

The workers will check all the vials inclouding the bottom neck ,bottom ,inerts.

The workers will pack 100pieces vials into one package.

The workers will send the package to sealing machine for packing.

FAQ+

WHAT TO CONSIDER WHEN SELECTING AN AUTOSAMPLER VIAL

Autosampler Compatibility

Not all autosamplers are alike. Some utilize robotic arms to pick up a sample vial; some use tray rotation while others move the sampling needle to the respective vial coordinates. The dimensions of autosampler vials vary. Most autosamplers are equipped with trays that use 12x32mm vial configurations but some like the Waters Wisp require a 15x45mm configuration. Consult your autosampler’s operating manual or manufacturer to determine the vial dimensions required.

Sample Volume

The amount of sample available for analysis is important in choosing the appropriate vial. If only a limited volume of sample is available, you will have to choose between using an insert for your regular autosampler vial, a microvial or a high recovery vial.

Note: Most 12x32 mm autosampler vials hold between 1.5mL to 2.0mL of liquid, depending on where the manufacture measures the vial full. The dimensions for 12x32mm vials are standard between manufacturers but the length of the neck and width/shape of the vial shoulder may vary. 12x32mm microvials have the same outer dimensions but the inside of the vial may be tapered to reduce volume or contain a fused insert. 12x32mm high recovery vials will have an internal conical bottom that allows for maximum sample recovery.

Sample Compatibility

The analyte and solvent compatibility should be considered in choosing vials and accessories. For example, amber glass is most often used for light sensitive samples while deactivated glass or plastic vials are used for compounds that are sensitive to glass or stick to the glass itself. Volatile samples require closures that reduce the risk of analyte loss due to evaporation.

Vial Composition

Several factors need to be considered when choosing laboratory glass - chemical inertness, durability, light sensitivity, storage conditions, analyte composition and especially exposure to heat/freezing temperatures.

Linear Coefficient of Expansion refers to the fractional change in the length of glass per degree of change in temperature, in short, the ability of the glass to tolerate rapid thermal changes. The lower the coefficient of expansion the better the glass can handle temperature change without fracturing.

Classifications for laboratory glass based on its resistance to attack from water were established by the United States Pharmacopoeia, USP.

USP Type 1, Class A, 33 Borosilicate Glass is the most inert and chemically resistant glass widely used in laboratories especially for chromatography applications. Type I glass is composed primarily of silicone and oxygen, with trace amounts of boron and sodium. It has the lowest leaching characteristics and a linear coefficient of expansion of 33.

USP Type 1, Class B, 51 Borosilicate Glass which is composed of silicone and oxygen, trace amounts of boron, sodium and other element is more alkaline than Class A glass but still adequate for laboratory use. All amber borosilicate glass is made of Class B unless otherwise specified and has an expansion coefficient of 51.

Silanized or deactivated glass is borosilicate glass that has undergone further deactivation by treating the surface of the glass with an organosilane. The surface becomes more hydrophobic and inert making the vial suitable for use with pH sensitive compounds, trace analyses and applications requiring long term sample storage.

USP Types II, III and NP glass are manufactured from soda lime which has less chemical resistance than borosilicate.

Polypropylene is a rigid and translucent material, which also comes in a variety of colours and has good chemical resistance for short term storage of most common laboratory chemicals.

Resistance decreases over time when using aromatic and halogenated hydrocarbons.

Polypropylene vials are often used for ion chromatography because of the extremely low metal content and excellent cleanability with dilute acid followed by deionized water rinse.

Polypropylene vials limit the exposure to hazardous materials since they can be incinerated while sealed.

Polymethylpentene (TPX) is a rigid transparent material, which has a relatively high melting point with a temperature range of 0°-170°C. TPX vials can be used as alternative to opaque polypropylene vials because they provide maximum clarity. Their chemical resistance is similar to that of polypropylene vials. TPX vials should be used for applications where visual clarity is required or repetitive exposure to higher temperatures such as autoclaving. TPX vials tend to be more brittle at room temperature.

Type of Vial Finish and Closures

Autosampler vials are available in a variety of neck finishes and opening diameters. Large mouth or wide ID vials have approximately a 40% wider mouth opening than standard opening vials. The large opening reduces the risk of bent autosampler needles during sampling.

Screw thread vials and caps provide low evaporation, reusability, less hand injury during manipulation than crimp seals and require no special tools. All screw threads vials and caps

are differentiated by their thread finish as defined by the Glass Packaging Institute, GPI. For screw thread vials, a two part number is assigned. For example, 8-425 neck finish represents a vial with a diameter of 8 mm across the outside of the threads and a thread style of 425.

Screw thread vials and caps are more expensive than crimp seals.

Caps for screw thread vials are available with either an open hole for autosampler use and standard addition or with a solid top for sample storage. One piece polypropylene cap and

membrane are also available. These pierceable screw thread caps are designed for one time use and reduce sample preparation time as there is no cap and seal to assemble.

Crimp top vials require lacquered aluminum crimp seals which are relatively inexpensive and, when properly assembled, provide the best seal for long term storage. Crimp seals are not reusuable.

A crimping tool is required to seal caps and a decrimper or decapper is required to remove the seals. Several types of hand crimpers are available including the adjustable precision

crimpers that Chromatographic Specialties offers. Adjustable hand crimpers feature an adjustable stop on the handle to provide consistent seal tightness every time. Adjusting the hex screw inside the steel crimper jaws will also alter the amount of crimp. Achieving a good crimp is crucial because overcrimping can cause septum coring, bent needles and create a larger hole in the Teflon septum layer than a properly crimped seal. Undercrimping can result in loose seals and sample evaporation.

Hand decrimpers quickly and safely remove seals with just a single squeeze of the handle.

Decappers are similar in design to pliers and provide an inexpensive alternative to decrimpers.

Decrimpers should be used for applications involving hazardous samples because there is less chance of spillage.

Electronic crimpers and decappers are also available. Electronic units reduce hand fatigue, provide consistent crimps and are ideal for laboratories analyzing a lot of samples.

Snap seal vials are less prone to breakage during decapping because more glass is used in the neck of the vial. The snap seal neck finish is compatible with either crimp and/or snap

seals and no special tools are required to remove the cap. These vials are recommended for short term sample storage and non-volatile samples because the seal is not as secure as a crimp or screw thread seal.

Shell Vials are an economical alternative to screw thread vials for Water’s HPLC autosamplers or any other autosampler that doesn’t use a robotic arm to move the vials. Most shells vials are sold with a polyethylene cap that has a starburst design for easy needle penetration.

WHAT TO CONSIDER WHEN SELECTING THE PROPER INSERT

Dimensions of the Autosampler Vial

Choosing the incorrect size of insert for an autosampler vial can result in poor reproducibility between sample injections, damage to the autosampler needle and an inadequate seal between the septum and the vial. The dimensions listed for insert size in the catalogue refer to the outside diameter and length. Inserts with an outside diameter of 5mm are used with vials with standard mouth openings and the 6mm are used with wide mouth vials. The length of the insert should be flush with the neck of the vial to prevent the

insert from causing the septum to bulge.

Conical inserts have a tapered bottom with pulled tips and are available with or without plastics springs. The spring acts as a shock absorber during needle penetration and raises the insert above the bottom of the vial, allowing greater sample recovery.

Mandrel inserts also have a tapered bottom but the tips have been precision formed over a mandrel to give the internal tip a “V” shape that reduces the residual volume of the insert. Mandrel precision formed inserts are recommended when maximum recovery of the sample is required.

Flat bottom inserts have the largest capacity and are the most economical inserts. These inserts are cylindrical in shape with a flat bottom

Hanging inserts have either a flange top or top spring that suspends the insert correctly centered in the vial.

Step inserts with a built-in glass flange are designed specifically for step vials with a special tapered neck. The flange suspends the insert correctly centered in the vial without causing a bulge in the septum when the cap is screwed on.

Limited volume inserts are an economical solution when there is a limited amount of sample and injection is done using an autosampler.

Most autosamplers have a set depth that the injection needle can go into the vial without bottoming out. Inserts increase the sample depth within the vial even if there is a very minute volume of sample available.

Solvent Compatibility

Type I borosilicate glass inserts are most commonly used for trace analysis in chromatography.

Polypropylene inserts are less expensive than glass and are suitable for applications involving pH sensitive samples.

Insert Shape and Point Style

The style of insert chosen is dependent on the amount of sample available and the residual volume after sampling.

WHAT TO CONSIDER WHEN SELECTING SEPTA

Septa Material Advantages Chemical Resistance Applications Max Temp

PTFE Economical Excellent For single injection only 550°C

PTFE/silicone Excellent resealing Excellent until punctured Multiple injections 200°C

capabilities Not suitable for chlorosilanes than moderate resistance

Pre-slit PTFE/silicone Reduces coring Excellent until punctured Multiple injections 200°C

Prevents vacuum from than moderate resistance

inside the vial

PTFE/silicone/PTFE Resistant to coring Excellent Above average resealing 200°C

Autoclavable Multiple injections or applications with long periods between injections

PTFE/red rubber Economical Excellent until punctured Moderate resealabililty 110°C not recommended for holding samples for further analysis

Molded polypropylene Economical Good For single injection use only 130°C

Not resealable

Gray butyl Very economical Not suitable for chlorinated Suitable for low pressure 125°C solvents, alkanes, benzenes applications or cyclohexanes

Viton Excellent chemical resistance Average resealability 160°C

Good for chlorinated solvents

Not recommended for use with amines, pyridine, acetonitrile, DMF, DMSO, THF, dioxane, methanol, Freon 22, ethylacetate, acetone or acid anhydrides.

Septum compatibility or chemical resistance with the sample and solvent is the main consideration when choosing vial septa. Any interaction can lead to sample degradation or the appearance of ghost peaks in the chromatogram. Teflon or PTFE is the most inert but has poor resealability making it unsuitable for multiple injections or storage. For layered septa such as PTFE/silicone the chemical resistance of the septa is that of Teflon until the septum is punctured. Once punctured, the silicone layer is exposed and able to react

with sample/solvent so the chemical resistance of silicone should be considered when using these septa.

Note: The thicker the facings on the seal the better the resealability but it compromises the ability of the autosampler needle to pierce

the septum.

Inquiry

If you have any question or comment, please contact us without hesitation. We will reply you as soon as possible. ( * is required information)

DO YOU HAVE A QUESTION REGARDING OUR PRODUCTS?

CONTACT US